❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

❅

Supply chains, the intricate networks that connect businesses and consumers, have faced unprecedented disruptions in recent years. From the COVID-19 pandemic's global reach to escalating geopolitical tensions and the accelerating impacts of climate change, these challenges have exposed vulnerabilities in traditional supply chain models. To thrive in this volatile environment, organizations must prioritize building resilient supply chains that can withstand shocks, adapt to change, and recover swiftly.

AI in supply chain management is emerging as a powerful catalyst for transforming these operations. By leveraging AI's capabilities, businesses can gain valuable insights, optimize operations, and proactively address potential risks. This introduction will explore how AI is revolutionizing supply chain management and its potential to create more resilient and sustainable supply chains.

AI: The Visionary for Supply Chain Visibility

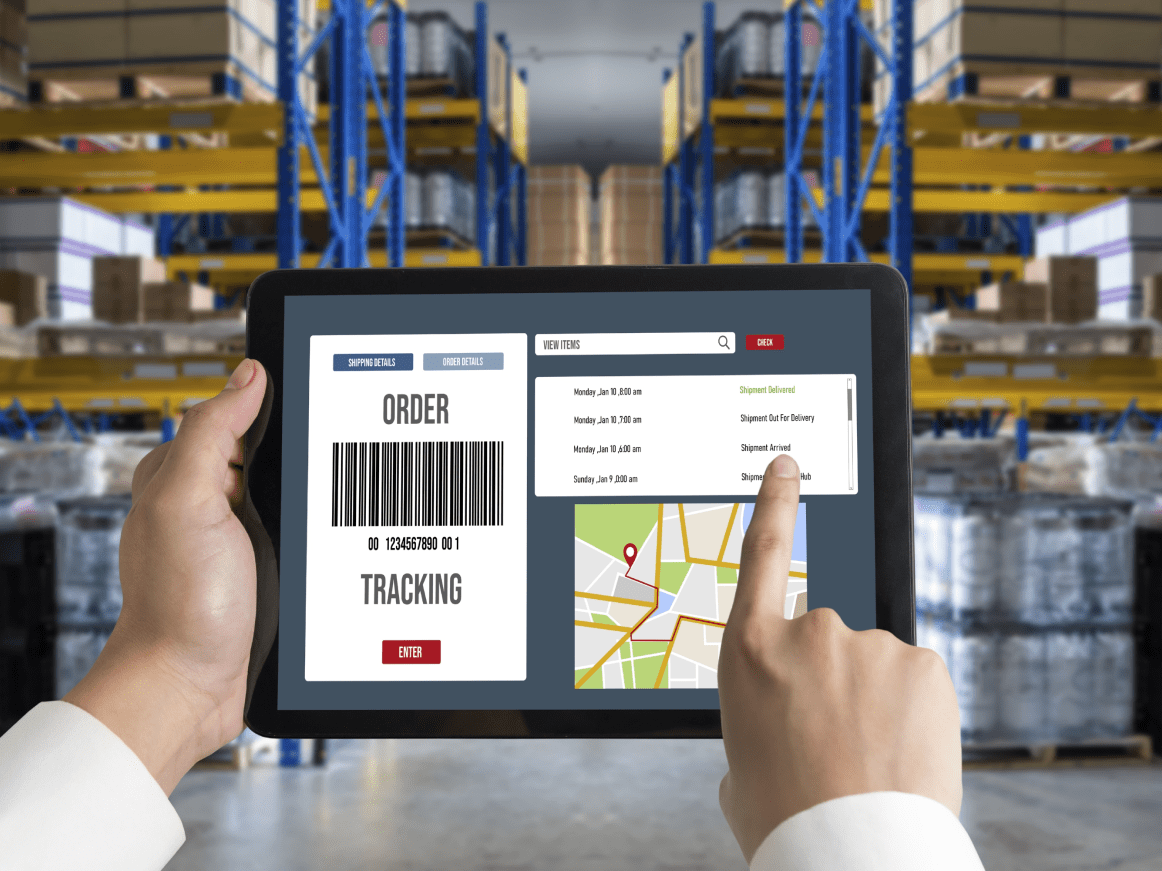

Supply chain visibility, the ability to accurately track and monitor the movement of goods throughout the supply chain, is a cornerstone of efficient and responsive operations. Traditional methods often struggle to provide real-time insights into the complex network of suppliers, manufacturers, transporters, and warehouses.

Artificial intelligence (AI) is transforming this landscape by offering unprecedented visibility. Through advanced data analytics, AI can process vast amounts of information to provide real-time insights into inventory levels, transportation routes, and supplier performance. This granular level of detail enables businesses to make informed decisions, identify potential disruptions, and optimize operations with greater precision.

By illuminating the often-opaque supply chain, AI empowers organizations to enhance their agility, reduce risks, and improve overall performance. As the foundation of an AI-driven supply chain, this visibility is critical for optimizing operations and responding proactively to disruptions.

AI: Enhancing Demand Forecasting and Inventory Management

Accurately forecasting demand has always been challenging. Traditional methods, relying on historical data and basic statistical models, can be unreliable in today’s dynamic market.

AI is revolutionizing demand prediction by analyzing extensive data sets—including sales history, customer behavior, economic indicators, and social media trends. AI algorithms uncover complex patterns that humans might miss, resulting in more accurate forecasts. This enables businesses to make informed decisions on production, inventory levels, and pricing.

AI also excels in optimizing inventory management. By integrating precise demand forecasts with real-time stock data and asset management for timely delivery of goods, AI helps businesses maintain optimal inventory levels, preventing stockouts and excess inventory. This approach not only reduces costs but also enhances customer satisfaction. Seaflux has worked on one such solution of asset tracking along with geofencing. Wherein the assets are tracked and managed using radio signals, without any internet communication, and predict their timely arrival to achieve the JIT (Just-in-time) approach, optimizing the inventory management.

AI for Supply Chain Optimization and Cost Reduction

AI is revolutionizing supply chain operations by enhancing efficiency and reducing costs. It finds the most cost-effective routes for transportation by analyzing data on traffic, weather, and fuel prices, leading to lower transportation costs and faster delivery.

In warehouses, AI optimizes storage, manages inventory, and automates tasks like picking and packing, which improves efficiency, cuts labor costs, and speeds up order fulfillment.

AI also identifies patterns and anomalies in supply chain data, uncovering cost-saving opportunities such as alternative suppliers or transportation modes. Many companies have already seen significant cost savings and efficiency gains from AI-driven optimization and supply chain automation.

AI for Supply Chain Risk Management and Building Resilient Supply Chains

AI in supply chain management enhances resilience by predicting potential disruptions such as supplier issues, transportation delays, or natural disasters. Predictive analytics in supply chain plays a critical role in anticipating these disruptions and enabling businesses to develop proactive strategies for risk mitigation.

AI also assesses risks across the supply chain, identifying vulnerabilities and areas for improvement. It can evaluate supplier reliability, transportation route risks, and geopolitical factors.

In the event of disruptions, AI speeds up recovery by optimizing logistics and distribution, ensuring quick delivery of essential goods, and finding alternative suppliers or routes. Artificial intelligence in logistics facilitates this recovery by improving route planning and transportation efficiency during such disruptions.

The Human Element in the AI-Driven Supply Chain

While AI is revolutionizing supply chain management, human expertise remains indispensable. The fear of job displacement is understandable, however, AI is more accurately seen as a tool to augment human capabilities. Humans bring critical thinking, problem-solving, and ethical considerations to the table, while AI provides data-driven insights and automation.

The successful integration of AI requires a workforce equipped with a blend of technical and soft skills. Supply chain professionals must become AI-literate, understanding how to leverage AI tools to optimize processes and make informed decisions. Collaboration between humans and AI is key to unlocking the full potential of this technology. By harnessing the strengths of both, organizations can build more agile, resilient, and efficient supply chains.

End Note: A Brighter Future with AI in Supply Chains

AI in supply chain management is revolutionizing operations by enhancing visibility, optimizing processes, and boosting resilience. Its benefits are clear: accurate demand forecasting, streamlined logistics, reduced costs, and the integration of intelligent supply chain solutions for further optimization.

To fully harness AI’s potential, ongoing investment in research and development is crucial for driving innovation and optimizing supply chains.

Businesses adopting AI are setting themselves up for long-term success. By leveraging AI and supply chain innovation, companies can create more agile, responsive, and sustainable supply chains. The future of supply chain management is promising, with AI at the forefront.

Krunal Bhimani

Business Development Executive