In this blog, we will go through the following heads and get into a few standards of Catena-X:

- What is Catena-X? How did it originate?

- Advantages of Catena-X

- Standards of Catena-X. Explained with an example

- How did Seaflux implement Catena-X for its client?

How was Catena-X originated and its purpose?

The supply chain across the automotive industry has been haywire for far too long, and that’s when the car manufacturers from Germany decided to come together and initiate a solution to address the growing need for seamless, transparent, and collaborative supply chain data sharing across the supply chain within the automotive industry. The increasing complexity of global supply networks, coupled with the demand for sustainability and compliance, led to the creation of Catena-X, a groundbreaking initiative that drives automotive industry innovation by enabling data-driven collaboration.

The Catena-X network was designed to serve as an open and standardized platform that fosters secure data sharing among car manufacturers' stakeholders, aiming to improve efficiency, drive innovation, and meet industry challenges collectively. The main purpose of Catena-X is to enable a data-driven ecosystem where partners can collaborate transparently and sustainably.

What is Catena-X?

Catena-X is an open network data ecosystem, developed specifically for the automotive industry to revolutionize data utilization among the stakeholders at each level. Manufacturers, suppliers, and service providers created the integrated data space in a standardized network within the Catena-X automotive network.

Catena-X is built on the principles of interoperability and data sovereignty and it ensures participants retain control over their data while enabling seamless collaboration. By fostering transparency, it provides a foundation for innovation, operational efficiency, and sustainable practices throughout the supply chain.

Advantages of Catena-X

Catena-X offers numerous advantages. It ensures data sovereignty, giving stakeholders full control over their data while benefiting from shared insights. The business benefits of Catena-X standards include streamlined operations, improved collaboration, and enhanced innovation across the supply chain. Its interoperability standards reduce inefficiencies, and the platform supports sustainability goals by improving traceability and accountability. Ultimately, Catena-X drives cost reduction, resilience, and technological advancements in the automotive supply network.

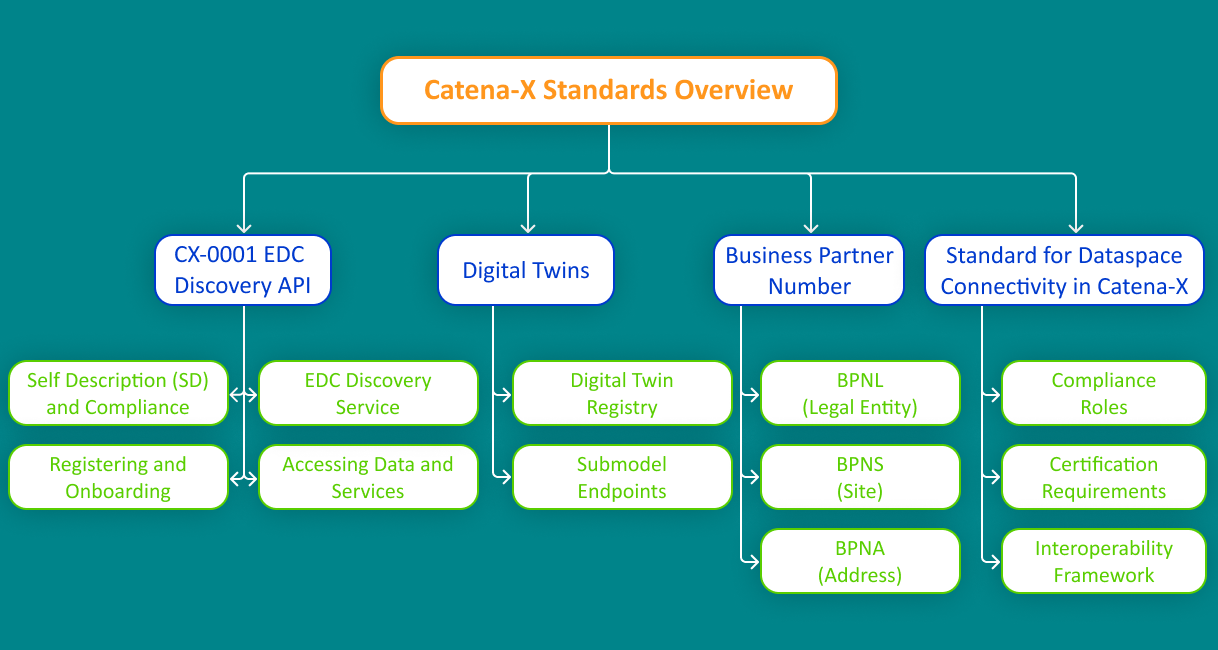

Catena-X Standards Overview

Let us now go through a few standards to understand their purpose, how it works, and a few more components. With our expertise in implementing these networks, understanding these standards can be invaluable for your next project.

1. CX-0001 EDC (External Data Connector) Discovery API

The main goal of the EDC Discovery API is to enable participants to find suitable EDC endpoints within the Catena-X automotive network. This is especially important as the network grows and more data becomes available.

Purpose:

- Simplifies the process of locating EDC endpoints.

- Ensures privacy by restricting searches to authorized participants using a BPN - Business Partner Number (covered in the coming standards).

Core Components:

1. Self Description (SD) and Compliance:

Each EDC endpoint within the Catena-X network must provide a SD document. This document describes the data and services offered by the EDC instance. The SD document helps participants understand what data is available and how to access it.

2. EDC Discovery Service:

The EDC Discovery Service is provided by the Core Service Provider. This service acts as a central point for discovering EDC instances that match specific criteria, such as the BPN number. Every EDC instance registered in the Catena-X network must be listed in this discovery service, ensuring that participants can easily find and connect to relevant data sources.

3. Registering and Onboarding:

To participate in the network, each EDC instance needs to go through a registration process. This process ensures that the EDC instance is compliant with the Catena-X standards and is properly listed in the discovery service.

4. Accessing Data and Services:

Once the EDC instance is registered, participants can use the discovery service to find it based on their BPN. The query results will provide the connector URL, allowing users to access the data or service offerings available at that EDC endpoint.

2. Digital Twins

As the name suggests, the Digital Twin is the digital copy of the physical asset. In the Catena-X automotive network, the Digital Twin standard establishes a framework to manage and access digital representations of physical assets.

Purpose:

- Acts as an address book for physical assets as digital copy, enabling efficient data discovery and interaction.

Core Components:

1. Digital Twin Registry:

Serves as a repository for Digital Twin records registered by data providers.Facilitates queries by data consumers to locate and interact with Digital Twins.

2. Submodel Endpoints:

Each Digital Twin includes references to Submodel endpoints that provide specific datasets. Ensures data compliance with semantic models to maintain consistency and usability.

3. Business Partner Number

The Business Partner Number (BPN) standard ensures consistent and unique identification of business partners within the Catena-X network.

Purpose:

- Streamlines data management and enhances collaboration.

- Reduces errors are and improves decision-making by maintaining high-quality data.

Core Components:

1. BPNL (Legal Entity)

Identifies the primary organization (e.g., company, university).

2. BPNS (Site):

Represents specific operational sites within a legal entity.

3. BPNA (Address):

Specifies the main address associated with each site.

Structure of BPN:

- BPNL1234567890ZZ

- BPNL: Legal entity identifier.

- 1234567890: Unique identifier.

- ZZ: Check digit for validation.

Key Features:

- Ensures consistency in identifying business partners.

- Supports multiple roles, including customer, supplier, and service provider.

- Enables seamless collaboration across the supply chain.

4. Standard for Dataspace Connectivity in Catena-X

The Dataspace Connectivity v.3.1.0 standard provides a framework for secure and interoperable data exchange within the Catena-X automotive network.

Purpose:

- Establishes guidelines for data sharing while ensuring sovereignty and security.

- Promotes effective collaboration without compromising data ownership

Core Components:

- Compliance Roles:

- Core Service Provider (A/B)

- Enablement Service Provider

- Business Application Provider

- Data Provider/Consumer

- Certification Requirements:

- Ensures all participants meet compliance standards.

- Maintains data security and interoperability.

- Interoperability Framework:

- Supports seamless data exchange across diverse systems and stakeholders.

- Promotes scalability and flexibility within the network.

How did Seaflux implement Catena-X for its client

At Seaflux, we leveraged the capabilities of Catena-X to revolutionize supply chain data sharing, enhance operational efficiency, and foster seamless collaboration across the supply chain ecosystem. Our expertise in integrating advanced technologies allowed us to effectively utilize the EDC Discovery API, simplifying the process of identifying and connecting to relevant EDC endpoints within the network. This approach not only streamlined data access but also ensured secure and compliant data sharing, giving our clients full control over the privacy of their data while maintaining the highest standards of operational excellence.

Additionally, project has embraced the Digital Twin framework to create digital representations of physical assets in our supply chain. With Catena-X's Business Partner Number (BPN) standard, we have ensured that every business partner within our network is uniquely identified, which reduces errors and enhances our ability to collaborate effectively across the supply chain.

Bhoomi Raval

Software Engineer